Construction Highlights for Modular Controlled Environment Rooms

Other Services

Introduction

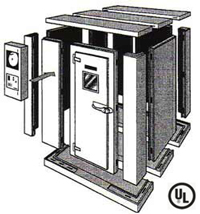

Modular Environmental Rooms are constructed from a flexible system of foamed in-place polyurethane panels. Surfaces are lined with corrosion-free metal finishes that are attractive and durable. The panels are locked together with camlock fasteners providing a tight vapor seal. Each panel is made with tongue and groove edges and uses a soft vinyl gasket for the seal. The non-hygroscopic insulation is foamed with non-CFC Freon gas and provides an overall U factor of 0.029 and R factor of 32.

The final room assembly offers a fire-safe construction that is UL listed. Entrance doors are flush with the outside front wall and are provide with a brushed or chrome hardware finish.

The internal safety release prevents anyone from being trapped inside the room. Observation windows, ramps, ports, and special floor finishes are standard options.

- Factory mutual approval available on steel based panels

- 10-Year Panel Warranty

- Calibration and validation support on various levels is also available.

Finishes - Many panel finishes are available on steel and aluminum base metal skins:

- Natural: Embossed or smooth aluminum, galvanized steel, or Galvalume

- Coated: Mill applied baked acrylic enamels; white is standard and recommended but other colors are available on request.

- Stainless Steel: 304 type with high polish or 2B finishes

Sizes